Recent technological advancements have ushered in a new era known as Industry 4.0.

This era is defined by the integration of technologies such as the Internet of Things (IoT), artificial intelligence (AI), machine learning, and augmented reality (AR), which increase efficiency, improve quality, and lower production costs. Among the innovations that have gained prominence in this digital age, the adoption of digital twins has emerged as a game-changer.

The Rise of Digital Twins

According to a forecast by Gartner, by 2021, half of the large industrial companies will be utilizing digital twins, leading to a significant 10% improvement in effectiveness. This prediction highlights the growing significance of digital twins in the industrial landscape. Digital twins have been incorporated by 13% of businesses that have started implementing IoT, and another 62% are either in the process of doing so or have plans to do so soon, according to research.

Unlocking the Potential of Digital Twins in Manufacturing

Digital twin development companies have witnessed significant adoption within the realm of manufacturing and have revolutionized traditional manufacturing practices. Digital twins, which NASA first used for space exploration programs, are now helpful across many industries, particularly in manufacturing. According to Gartner, a digital twin is a software design pattern that simulates a physical object to understand its state, react to changes, enhance business processes, and add value.

IIoT: Revolutionizing Manufacturing with Digital Twins

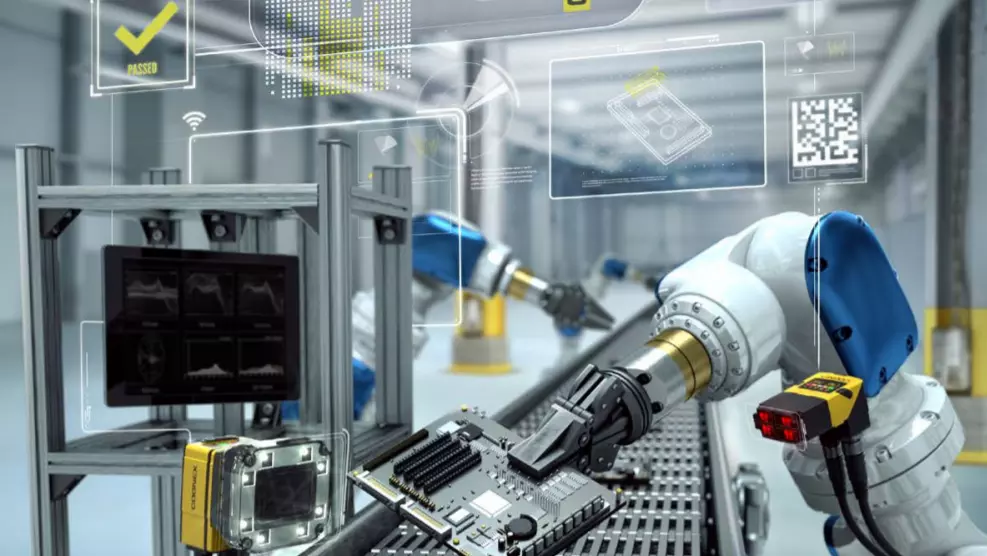

Manufacturers have embraced the Industrial Internet of Things (IIoT) to enhance business functions. Manufacturers can gather valuable data by leveraging sensors and connected devices to improve the entire product life cycle, including services and supply chain operations. Integrating digital twins with IIoT enables manufacturers to plan, experiment, predict, analyze, and implement strategies more effectively, significantly saving costs, time, and resources.

From Concept to Reality: Using Digital Twins in Manufacturing

Digital twins play a pivotal role in streamlining operations throughout the product life cycle in the manufacturing sector. Manufacturers can utilize digital models to analyze potential errors, simulate various outcomes, and optimize their production processes before physically bringing the product to market. Prominent examples include Tesla, which utilizes real-time IoT data and digital twins to improve the efficiency and performance of their vehicles, and Kaeser compressors. This manufacturing company uses digital twins to foresee potential failures and reduce downtime.

AI: Powering Manufacturing Advancements through Digital Twins

Artificial Intelligence (AI) is a driving force behind the advancements witnessed in Industry 4.0, and its integration with digital twins holds immense potential for manufacturers. Manufacturers can identify complex virtual scenarios by combining AI algorithms with digital twins, optimize product quality, and enhance efficiency. AI, machine learning, and deep learning techniques enable manufacturers to comprehend and analyze complex virtual data, exploring multiple variables that may not be possible with real-world data alone.

Augmented Reality and Digital Twins: Shaping the Future

Augmented reality (AR) is a powerful tool with digital twins that enables manufacturers to create immersive data visualizations and extract valuable insights from complex datasets. AR allows manufacturers to overlay digital information onto physical assets, facilitating training, providing real-time insights, and aiding in issue detection. Incorporating mixed reality further enhances these capabilities, enabling workers to visualize machinery and access key data outputs, ultimately improving efficiency and reducing turnaround time.

Digital Twins Beyond Manufacturing

While manufacturing has been at the forefront of leveraging digital twins, other industries are also adopting this technology. In the retail sector, the combination of augmented reality and digital twins allows retailers to create digital replicas of physical products, enabling customers to visualize them in real-world settings. This approach minimizes inventory loss and enhances security. Similarly, digital twins enable providers to experiment in simulated environments, optimize patient treatments, and maintain healthcare equipment effectively, preventing workflow disruptions.

Summing Up

As more industries undergo digital transformation, the seamless integration of IoT, AI, and other cutting-edge technologies with digital twins will continue to yield impressive results. Businesses can optimize digital twin development costs, resources, and product quality with data at the core of digital twins. While large corporations have readily embraced digital twins, there is still significant potential for small and medium-sized businesses and other industry sectors to benefit from this innovative approach in their strategic decision-making processes.

Source: BBN Times